New container dumper solves persistent industry problems

There’s a new container dumper in town, offering revolutionary benefits that will tackle industry challenges commonly associated with hydraulic container dumpers regarding speed, messy hydraulic fluids, space constraints, and overhead clearance limitations. Industry problems persisted, and Endura-Veyor, Inc. innovated a dumper that elevates the dependability and versatility of their industry-leading Container Dumper Line with the invention of an unrivaled novel design.

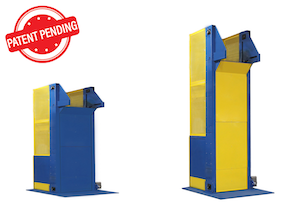

Endura-Veyor’s patent pending Optimizer Container Dumper defies immutable ceiling height, overhead clearance, and floor space limitations while outperforming hydraulic dumpers in virtually every category. Optimizer Container Dumper models are structurally and mechanically designed to overcome restrictions that limit typical dumpers from performing.

Endura-Veyor’s patent pending Optimizer Container Dumper defies immutable ceiling height, overhead clearance, and floor space limitations while outperforming hydraulic dumpers in virtually every category. Optimizer Container Dumper models are structurally and mechanically designed to overcome restrictions that limit typical dumpers from performing.

These hydraulic-free dumpers operate much quieter and significantly extend the horizontal reach to unload bulk and loose material into receiving equipment within a small footprint. A unique rotational design enables drums to rotate in a manner that evades overhead clearance interferences, even with higher discharge height requirements.

Models are driven by dual oversized chains with built-in redundancy that provide extra strength, lifting power, and increased reliability for various processing, handling, sorting, storage, or receiving operations.

Benefits of Optimizer Container Dumper models include:

- Smaller footprint

- Significantly reduced overhead clearance requirements

- Greater horizontal reach

- Fast cycle speed

- Hydraulic-free

- Quiet operation

- Higher discharge height

To fulfill a broad range of customer needs, Endura-Veyor has developed two model types: Optimizer and Hi-Lift Optimizer. Dump or discharge height requirements will primarily determine the model that will be best for each application.

Optimizers reach dump heights of up to 102 inches, while Hi-Lift Optimizers start dumping from heights of nine feet, can reach up to 20 feet, and include a full height enclosure as an added safety measure.

What makes Hi-Lift Optimizers unique is their ability to cycle up to 50% faster and lift various container types higher than hydraulic lift and dump models. In addition, these models can be built with multiple discharge height positions, allowing them to feed various pieces of equipment, which further increases achievable space savings and plant efficiency.

Both models benefit from the innovative design that saves more floor space than traditional dumpers. A smaller footprint means more space for forklifts and pallet jacks to maneuver and load containers into our game-changing dumpers to efficiently feed downstream equipment that handle, sort, manufacture, process, and produce across all industries.

Traditionally, in order to achieve specific discharge heights, tall drums are required—not the case with Optimizer Container Dumpers. The patent pending design equips models with the ability to unload various types of containers while evading potential overhead clearance interferences. As if that is not enough, both models can provide greater control that benefits certain applications like material metering, by slowing or stopping the rotating drum at any position during the dump cycle.

Being chain driven, hydraulic fluid, maintenance, and contamination concerns are eliminated. While hydraulic-driven dumpers are known for their power, they require more overhead clearance in accordance with the lift. The Optimizer models’ dual oversized chains have the necessary power as well as built-in redundancy, adding extra performance assurance when lifting and dumping various container types and sizes up to 2,000 pounds.

These hydraulic-free dumpers operate much quieter and significantly extend the horizontal reach to shorten the gap between receiving equipment within a small footprint. When dumping and unloading bulk and loose material into equipment that is either difficult to access due to space restrictions, or even concerns of interfering with the equipment itself, these innovative models will be transformative, as they have been strategically designed to more than double the horizontal discharge reach, articulate, and effectively perform in tricky unloading conditions.

Standard controls for both model types include a PLC, an HMI screen or user-friendly push buttons, auto-lube chain, and cycle tracking. Options include auto-run mode, maintenance suggestions, and customizable advanced metering functionality. Available structural options include custom drum sizes, chutes, and features of gated enclosures, light curtains, and swing, slide, or lift doors.

A container dumper with a smaller footprint, less overhead clearance required, and increased productivity, all backed by Endura-Veyor’s quality reputation and professional employees who listen to customer needs.